The best future

— Aiming for a goal that everyone can agree on

— Share your opinions and shape them

— Providing joy and value to customers

A bright future for everyone involved!

— Aiming for a goal that everyone can agree on

— Share your opinions and shape them

— Providing joy and value to customers

A bright future for everyone involved!

We regard our products as rough stones for providing special value,

by repeatedly pioneering new areas, we will shift to electronic devices.

In addition, we are actively working to build an environment-friendly and appropriate working environment.

We aim to contribute to a sustainable future that exceeds the expectations of all stakeholders!

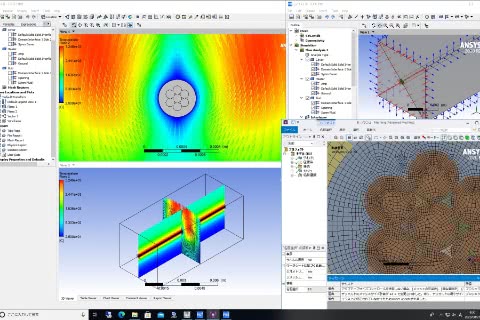

Continuous narrowing of product pitch

Miniaturization including peripheral parts

Improved heat resistance, withstand voltage performance, and miniaturization

Thermal control on a local basis

Reduced signal loss during high-speed communication

Rapid response to improvement cycle

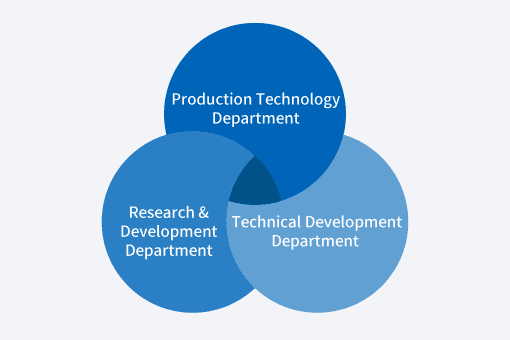

Internal collaboration

By working together with the production technology department of the manufacturing division to address common technical issues, we aim to speed up development and improve operational efficiency.

Affiliated company collaboration

We will promote technology fusion and development of items for overseas by bringing together technologies with domestic and overseas subsidiaries and affiliates.

Industry-academia collaboration

We are working on joint research with universities and AIST in order to increase opportunities for technological breakthroughs, unitization, and idea creation.

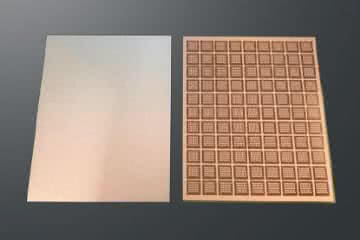

High thermal conductivity/low elasticity resin substrate

High frequency probe card

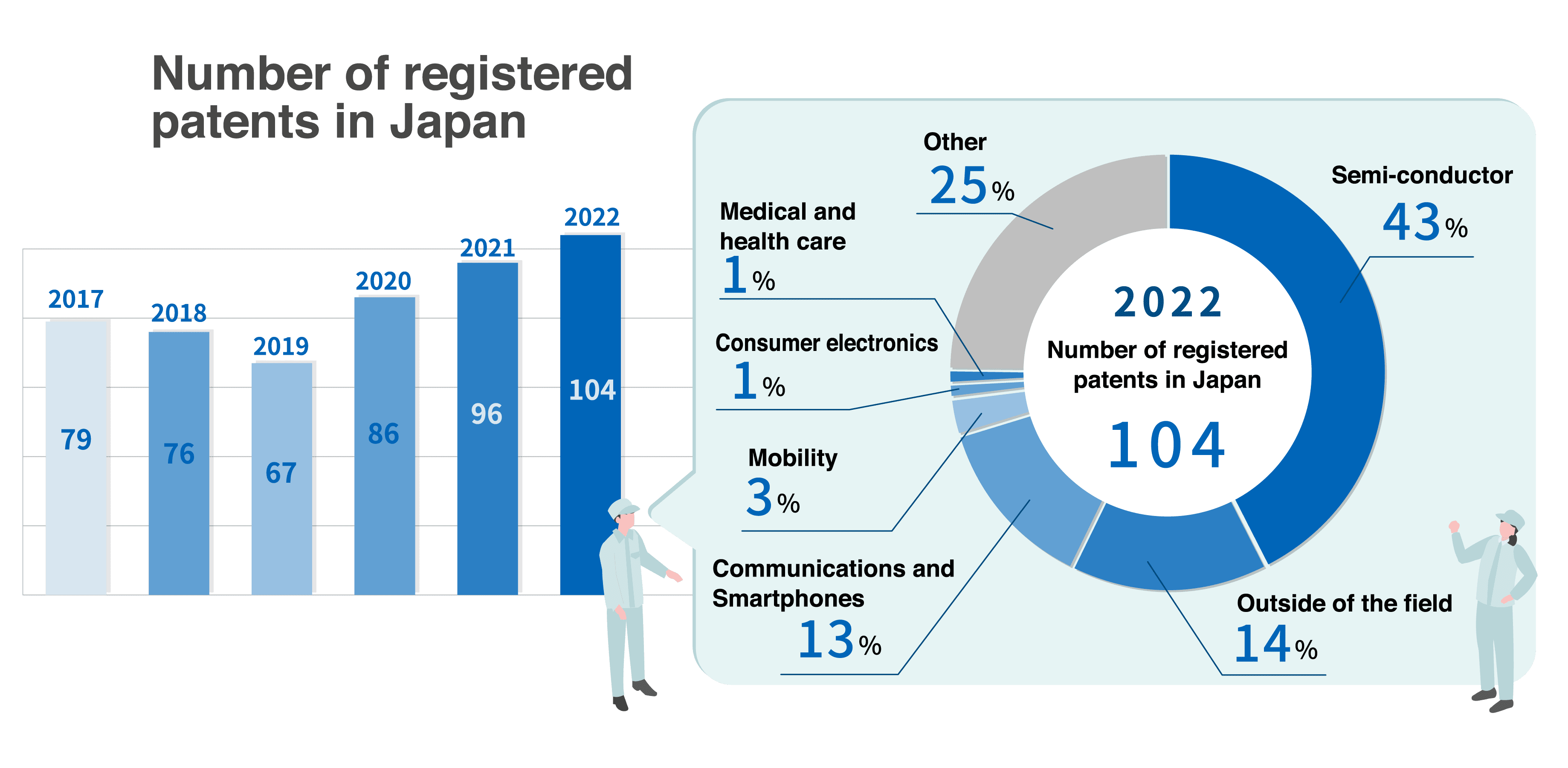

Patent registrations have been steadily increasing since 2019, and as of the end of 2022, 104 patents have been registered in Japan.

In the future, based on the development vision introduced above, we will not only deepen existing businesses but also develop new businesses. We will expand our intellectual property rights in a wide range of areas while conducting research.

Top Research and Development